NEWS / Jinghua Glasswork

Condiment Cruet production process

Categories:

Time of issue:

Aug 02,2021

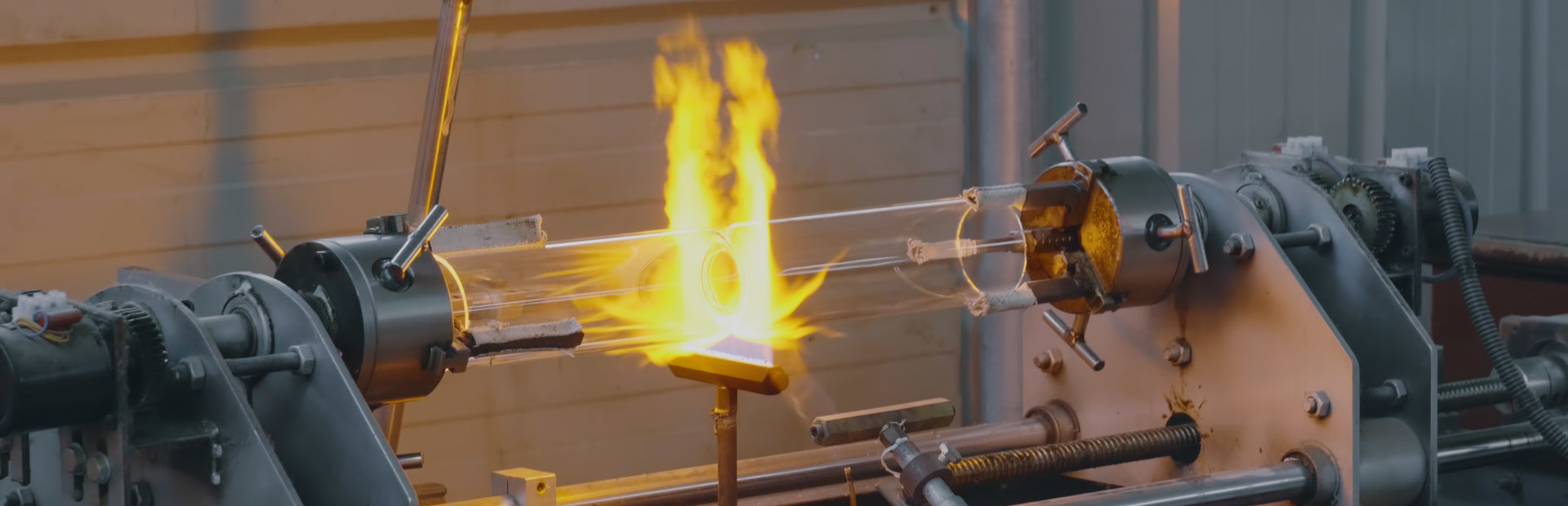

First, condiment Cruet manufacturers must design, determine and manufacture the Condiment Cruet mold. The glass raw material uses quartz sand as the main raw material, and other auxiliary materials are melted into a liquid at high temperature, and then injected into the mold, cooled, cut, and tempered to form a Condiment Cruet. Condiment Cruet generally has a rigid logo, and the logo is also made of a mold shape. The molding of Condiment Cruet can be divided into three types according to the manufacturing method: manual blowing, mechanical blowing and extrusion molding. Condiment Cruet can be divided into the following types according to the composition: one is soda glass, the other is lead glass, and the third is borosilicate glass.

The main raw materials of Condiment Cruet are natural ore, quartz stone, caustic soda, limestone, etc. Condiment Cruet has a high degree of transparency and corrosion resistance, and the material properties will not change in contact with most chemicals. The manufacturing process is simple, the shape is free and changeable, the hardness is large, heat-resistant, clean, easy to clean, and can be used repeatedly. Condiment Cruet as a packaging material is mainly used in food, oil, wine, beverages, condiments, cosmetics and liquid chemical products, etc., and has a wide range of uses. But Condiment Cruet also has its shortcomings, such as large weight, high transportation and storage costs, and inability to withstand impact.

Condiment Cruet use characteristics and types: Condiment Cruet is the main packaging container for food, medicine, and chemical industries. They have good chemical stability; easy to seal, good airtightness, and transparency, and the contents of the contents can be observed from the outside; good storage performance; smooth surface, easy to disinfect and sterilize; beautiful appearance, colorful decoration; certain machinery Strength, can withstand the pressure in the bottle and external force during transportation; the advantages of wide distribution of raw materials and low price. Its disadvantages are high quality, high brittleness and fragility. However, in recent years, the use of new technologies such as thin-walled and lightweight and physical and chemical tempering has significantly improved these shortcomings. Therefore, Condiment Cruet is able to compete with plastics, iron cans, and iron cans to increase its output year by year.

Condiment Cruet has a wide range of varieties, from small bottles with a capacity of 1ML to large bottles of more than ten liters, from round, square, to special-shaped and handle bottles, from colorless transparent amber, green, blue, black shading bottles and opaque The number of opalescent glass bottles, etc. are too numerous to mention.

Keyword:

Condiment,Cruet,Condiment,Cruet,manufacturers,Condiment,Cruet,material,good,price,and,quality,Condiment,Cruet

Relevant information

Aug 07,2023

The Benefits of Screw Glass Water Bottles for Everyday Use

Aug 07,2023

The Benefits of Using a Screw Glass Water Bottle for Your Daily Water Intake

Aug 06,2023

The Benefits of Screw Glass Water Bottles for Everyday Use